Leaded Glass Options

There are many leaded glass finishes such as Soldered, Antique or even Iron and they can all create the perfect look that you are trying to achieve. Pricing for options 1 & 2 are included in any quote you receive, if you require soldered lead or any of the other options, please ask for a quote including your preferred lead finish. The lead strip will be applied to both sides of the glass and if colour is required, this will be in the form of Overlay Stained Glass film and will be located under the lead strip on the inside face of the glass.

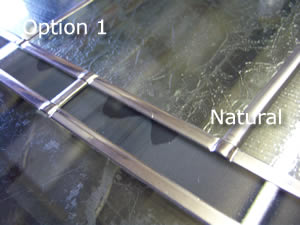

Option 1 – Natural Lead

Option 1 – Natural Lead

A natural lead finish is created by using pure lead that will start life as a bright silver colour but over time will become dull and grey as it oxidises.

When oxidation occurs the lead will discolour and may even leave a white residue but eventually the lead will become a consistent grey colour. Where the lead meets up with other lead, the joints are ‘boned’ down (crossed over) in the direction of the lead.

This lead has been the most popular choice of lead over the years and gives a great traditional appearance as long as the lead is cleaned on a weekly basis for the first few months or years. This lead strip has a slightly domed profile.

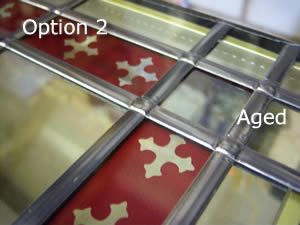

Option 2 – Aged Lead

Option 2 – Aged Lead

Also known as ‘antique lead’ finish, this lead strip is by far the most popular choice for stained glass windows and doors. The application process is the same as Option 1 but this aged lead is pre-aged with a powder coating colour coat during manufacture of the lead so this will reduce the chances of the lead oxidising through time although oxidation can still occur.

This lead has a dark reflective appearance that helps make the design more prominent compared with the natural lead finish. One of the few drawbacks to this lead is the inconsistency in batch variation. One batch of lead may appear darker or lighter than another batch of lead so exact matches cannot be guaranteed if orders are placed at different times. When different thicknesses of lead are used on the same glass panel, there may also be a variation in colour of the two lead profiles but both will be ‘aged’. This lead strip has a slightly domed profile.

Option 3 – Natural Soldered Lead

Option 3 – Natural Soldered Lead

This leaded glass finish is created by using the natural lead from Option 1 and instead of connecting the various sections of lead together using the ‘boned’ method the lead is soldered together using the same technique as used in traditional stained glass.

As this is natural lead, the lead will again start off with a bright silver appearance and it will gradually oxidise and become a dull grey in appearance as with Option 1 above. This lead should be cleaned regularly over the first few months to avoid staining of the glass and the lead itself. This lead strip has a slightly domed profile.

Option 4 – Aged & Soldered

Option 4 – Aged & Soldered

The aged and soldered finish is created by using natural lead and solder as described in Option 3 with the addition of a darkening chemical added to the lead after soldering. This sheen chemical instantly ages the lead giving it a darker appearance.

As this lead is not colour coated it will still oxidise over time and will discolour with a white discharge until it stabilises to give a consistent dark finish.

In the unlikely case that you want the design to be produced directly onto the Pilkington K glass (which is usually the clear backing glass on a double glazed unit), we cannot do this with aged and soldered lead as the sheening process damages the Pilkington K glass. If the Pilkington K glass is used as the backing glass which is normally the case, there is no issue with having aged and soldered lead.

Option 1 – Natural Lead

Option 1 – Natural Lead